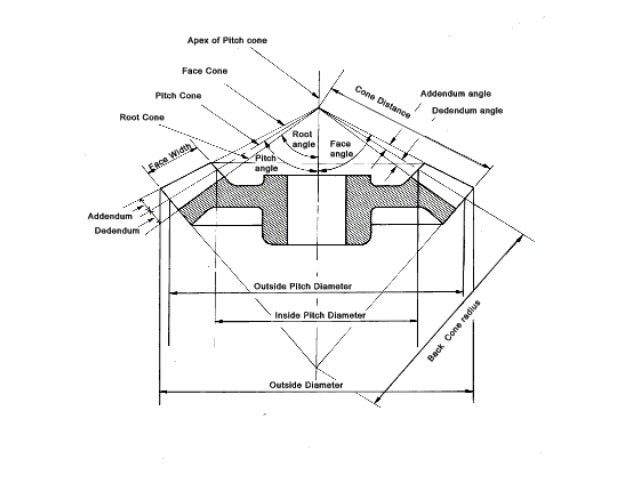

Miter bevel gears are a special class of bevel gear where the gear shafts intersect at 90 each of the two gears has a 45 pitch angle and both gears have the same number of teeth ie the gear ratio is 11. The specifications for the design are the power requirements the gear ratio pinion speed and the material properties. Bevel gear design procedure.

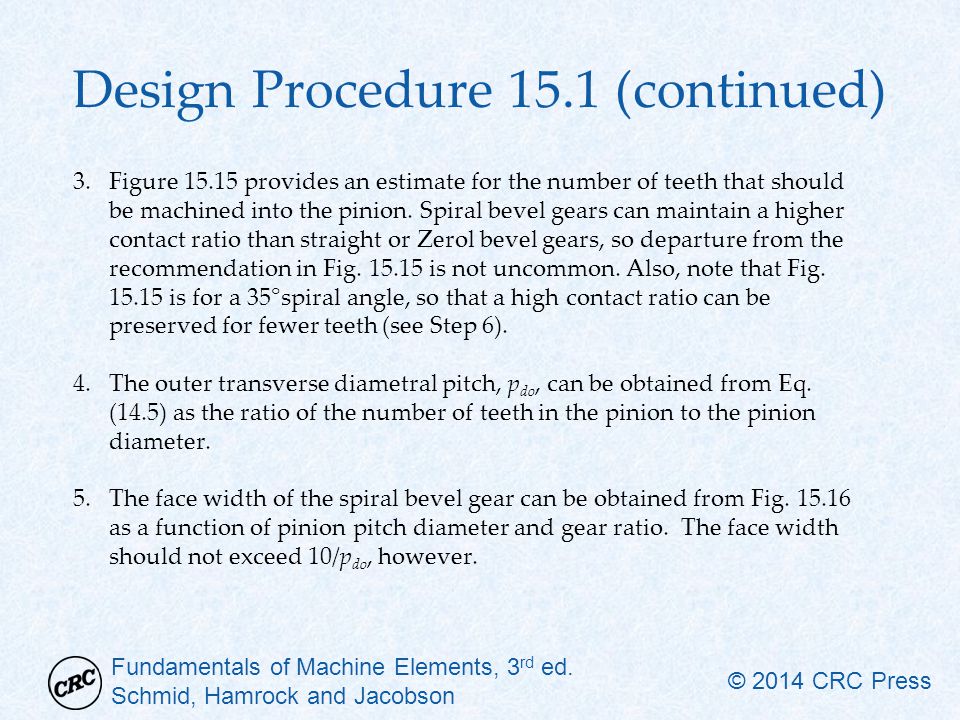

Bevel Gear Design Procedure, Miter gears may be of straight or spiral tooth profile. This paper describes the design of a straight bevel gearset with the objective of minimizing the enclosed volume. Average module mav can be calculated based on the beam strength using the equation DESIGN PROCEDURE FOR BEVEL GEARS 5.

Bevel Gear In SolidWorks Exercise 5 in SolidWorks. Clarify specifications and determine basic elements. If a bevel gear is mounted on a shaft far from the bearings the shaft may bend. Check spur gears strength.

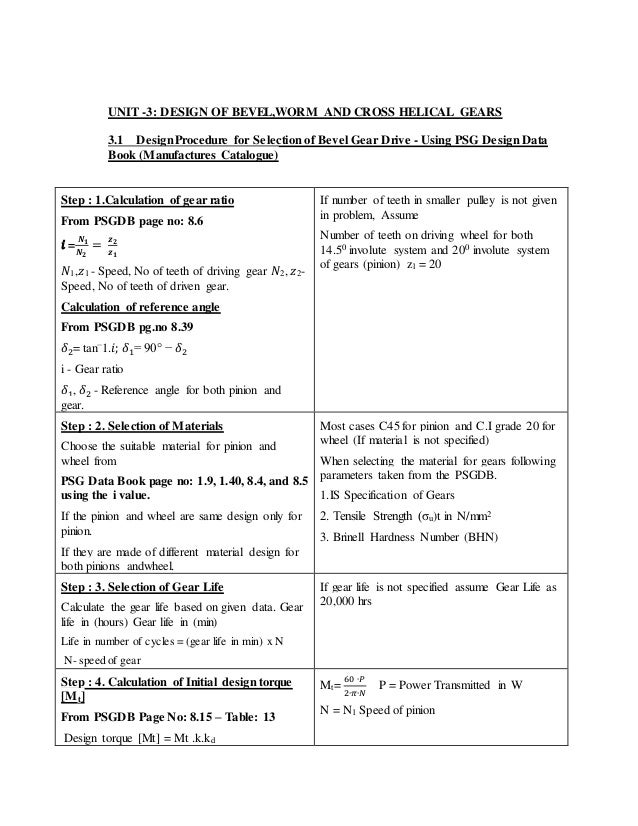

Calculation of gear ratio i and pitch angle.

Beyta Gear Service Charles D. Schultz All rights reserved. Since almost all mechanical designs use gears and cogs they are very useful to know. Thermal capacity materials -forces and stresses efficiency estimating the size of the worm gear pair. If a bevel gear is mounted on a shaft far from the bearings the shaft may bend. You cannot install bevel gears in the same manner as spur and helical gears and expect them to behave and perform as well.

Read another article:

Source: youtube.com

Source: youtube.com

The objective of this project was to develop an automated process for modeling spiral bevel gears to reduce gear design time. This paper describes the design of a straight bevel gearset with the objective of minimizing the enclosed volume. As the popularity of five-axis CNC machine tools and multi-axis CAM software has increased such tools are now being used to manufacture these types of. Where NA and NB speed of the driver and driven respectively and ZA and ZB. Bevel Gear Design Procedure Steps How To Calculate Module Of Bevel Gear Youtube.

Source: youtube.com

Source: youtube.com

As the popularity of five-axis CNC machine tools and multi-axis CAM software has increased such tools are now being used to manufacture these types of. Design procedure for Bevel Gear. Is outlined as follows. Design procedure for Bevel Gear. Bevel Gear Design Procedure Steps How To Calculate Module Of Bevel Gear Youtube.

Source: geartechnology.com

Source: geartechnology.com

The pitch surface of bevel gears is a cone. Schultz Beyta Gear Service. These gears are also easier to design to fit given centre distances because there are more parameters that can be rearranged. Where n a and n b speed of the driver and driven respectively and z a and z b number of teeth on driver and driven respectively. A Practical Approach For Modeling A Bevel Gear Gear Technology March April 2015.

Source: slideshare.net

Source: slideshare.net

Thermal capacity materials -forces and stresses efficiency estimating the size of the worm gear pair. If a bevel gear is mounted on a shaft far from the bearings the shaft may bend. UNIT IV DESIGN OF GEAR BOXES. Helical gears are superior to spur gears in most applications especially where noise must be kept to a minimum or the pitch line speed is in excess of 10 ms. Introduction Design Of Bevel Gears.

Source: researchgate.net

Source: researchgate.net

Bevel Gear In SolidWorks Exercise 5 in SolidWorks. This study reviews the Procedural steps algorithms involved in the design of bevel gears and the development of the software package Bevel CAD which is to be used in designing bevel gears. Beyta Gear Service Charles D. Schultz All rights reserved. Procedure For The Geometrical Synthesis Of A Straight Bevel Gear Iso Download Scientific Diagram.

Source: pdfprof.com

Source: pdfprof.com

Calculation of gear ratio i and pitch angle. Terminology -helix angles -Estimating the size of the pair of cross helical gears. Speed of pinion and gear are Np 500 RPM and Ng 250 RPM respectively. Minimum cone distanceR can be determined by using equation 4. Design Procedure Of Helical Gear.

Source: sdp-si.com

Source: sdp-si.com

In this series we explain how to design gears and peripheral parts according to procedures using simple mechanisms. Schultz All rights reserved. UNIT IV DESIGN OF GEAR BOXES. Minimum cone distanceR can be determined by using equation 4. Helical Gear Calculations Crossed Helical Gear Meshes And Bevel Gearing Sdpsi.

If a bevel gear is mounted on a shaft far from the bearings the shaft may bend. The pitch surface of bevel gears is a cone. Select the number of teeth for the pinion and the g. I recommend that you play around and try to create different cogs and gears. How To Determine The Module Of A Spiral Bevel Gear Set Quora.

Source: slideplayer.com

Source: slideplayer.com

Calculation of gear ratio i and pitch angle. Bevel gears should be fastened to the shaft with keys and set screws taper pins step shafts etc. Design procedure for Bevel Gear. Clarify specifications and determine basic elements. Chapter 15 Helical Bevel And Worm Gears Ppt Video Online Download.

Source: studylib.net

Source: studylib.net

DESIGN PROCEDURE FOR HELICAL GEAR. Bevel gears should be fastened to the shaft with keys and set screws taper pins step shafts etc. Design of peripheral structures of gears. Calculation of gear ratio i and pitch angle Selection of material. Design And Analysis Of A Spiral Bevel Gear.

Source: semanticscholar.org

Source: semanticscholar.org

110 depicts a typical miter gear arrangement. Clarify specifications and determine basic elements. I recommend that you play around and try to create different cogs and gears. October 1 1990 - AGMA. Figure 16 From Design And Analysis Of A Spiral Bevel Gear Semantic Scholar.

Design procedure for Bevel Gear. To optimize the performance of any two bevel gears the gears must be positioned together so that they run smoothly without binding andor excessive backlash. Check spur gears strength. Bevel gears should be fastened to the shaft with keys and set screws taper pins step shafts etc. Agma Design Procedure For Spur And Helical Gears Download Scientific Diagram.

Source: researchgate.net

Source: researchgate.net

These gears are also easier to design to fit given centre distances because there are more parameters that can be rearranged. This study reviews the Procedural steps algorithms involved in the design of bevel gears and the development of the software package Bevel CAD which is to be used in designing bevel gears. Exercises in calculating gear dimension sheets the use of Gleason time sharing computer programs and the evaluation of resulting stress data. Beyta Gear Service Charles D. Pdf Design And Calculation Of Planetary Transmission With Bevel Gears.

Source: youtube.com

Source: youtube.com

Some typical bevel gear The most common gear-cutting processes include hobbing broaching milling and grinding. Where N A and N B speed of the driver and driven respectively and Z A and Z B Number of teeth on driver and driven respectively. The objective of this project was to develop an automated process for modeling spiral bevel gears to reduce gear design time. If a bevel gear is mounted on a shaft far from the bearings the shaft may bend. Design Of Bevel Gear I Youtube.

Source: slideplayer.com

Source: slideplayer.com

October 1 1990 - AGMA. DESIGN PROCEDURE FOR BEVEL GEARS From the requirements choose suitable materials for pinion and gear tooth profile and pressure angle are selected. The sum of the pitch angles of spiral bevel gears is equal to the shaft angle. As the popularity of five-axis CNC machine tools and multi-axis CAM software has increased such tools are now being used to manufacture these types of. Chapter 15 Helical Bevel And Worm Gears Ppt Video Online Download.