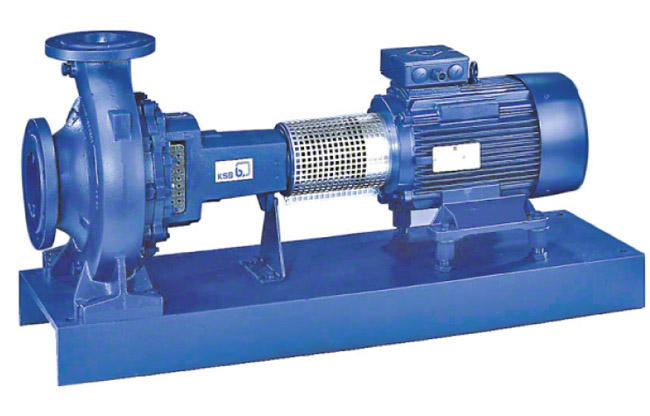

MeghaTech Engineers are Manufacturer and Exporter of piston valvesBack Pullout PumpsPump ManufacturerSelf priming Non Clog PumpsValves ManufacturerPiston Valves ManufacturerAhmedabad GujaratIndia. Top Vertical Closed impeller with three-dimensionally curved vanes. Back pullout pump design.

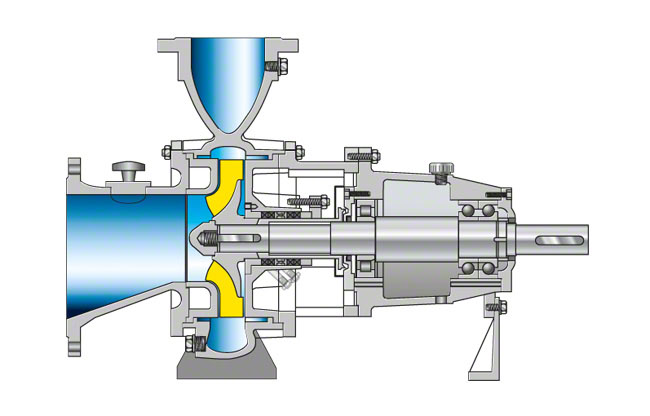

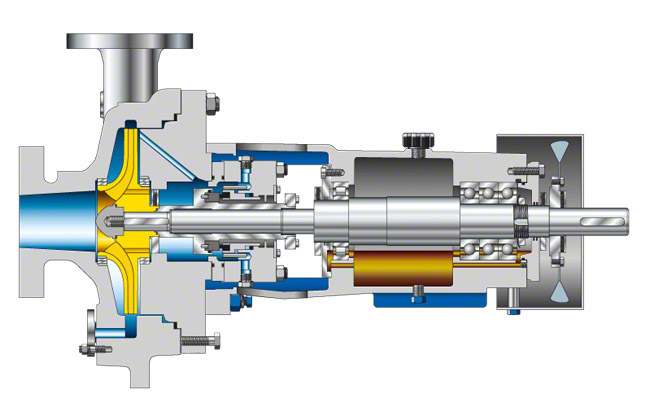

Back Pullout Pump Design, Back pull-out design refers to a centrifugal pump design type which meets refineries requirements for rapid dismantling and re-assembly and is therefore often used for process pumpsThe advantage of this design is that the rotating assembly including bearings and shaft seals can be pulled out of the pump casing once the motor has been decoupled and the connection flange unscrewed. All components which are in contact with the liquid are made of SICcast. PEW split case pumps come with horizontal pump shaft and volute casing which can be dismantled in the horizontal plane along the drive shaft.

Pin On Wilo Pumps From in.pinterest.com

Pin On Wilo Pumps From in.pinterest.com

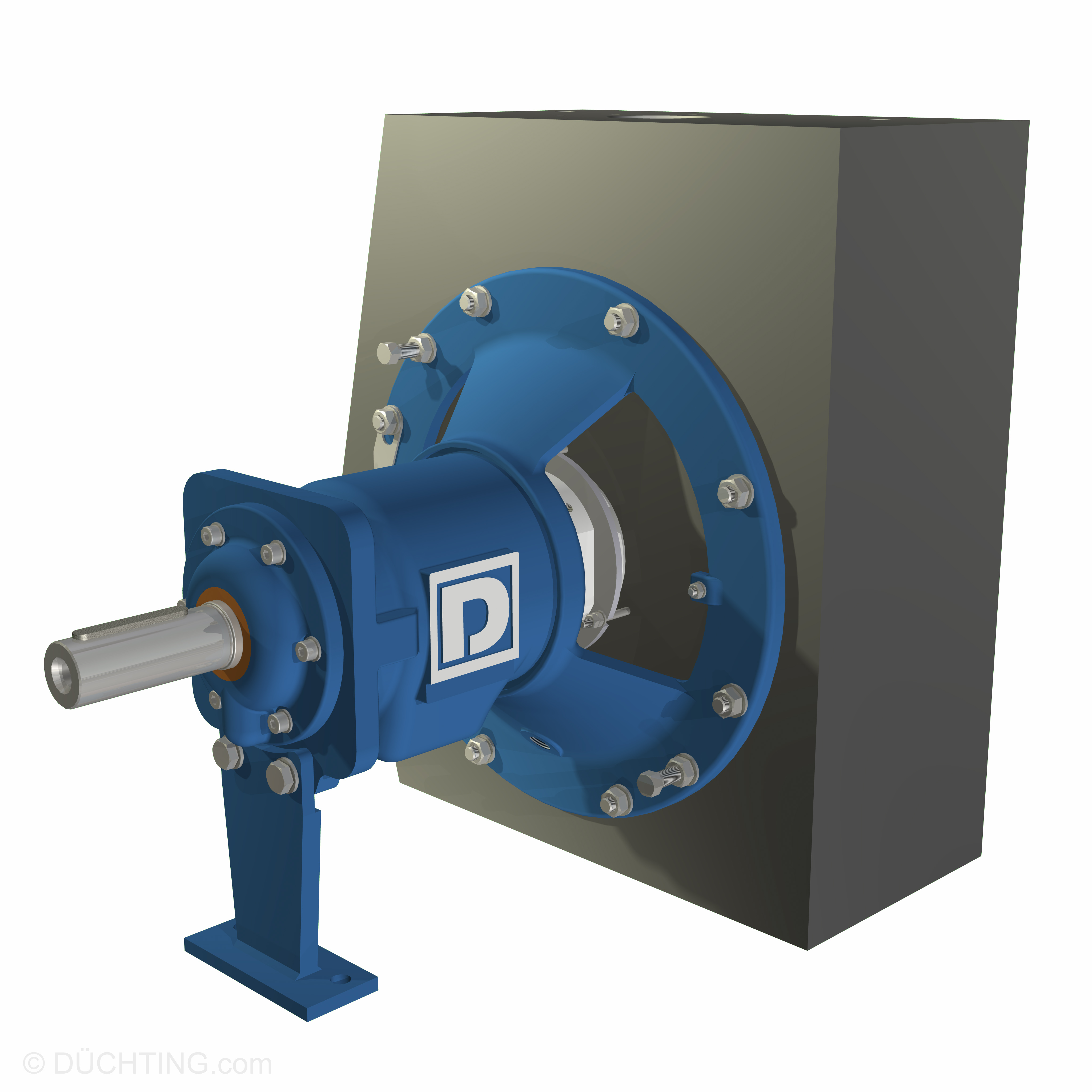

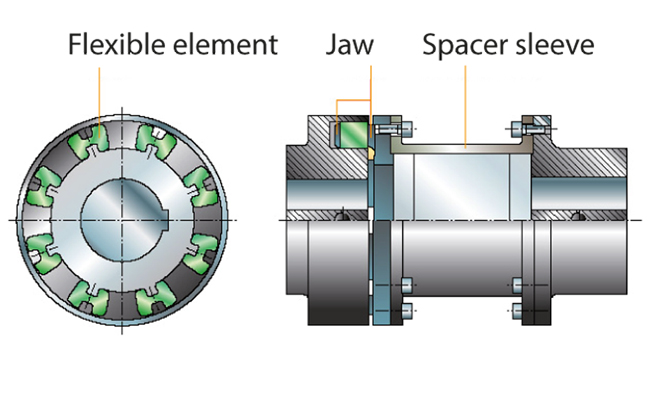

KWP Pump in Back Pull-out Design for Solids-laden Fluids Materials EN-GJL-250A48 CL 35B EN-GJS-400-18-LT ERN CeramikPolySiC NORIHARD NH 15 3 NORILOY NL 25 2 NORIDUR 14593 NORICROM 14475 NORIDUR 14593 DAS NORICLOR 14573 Technical data Pump size DN 40 to 900 Flow rate Up to 17000 m3h Discharge head Up to 100 m 1. EASYFLOW BACK PULL-OUT FEATURE. The Paragon PA Series pumps can be used for the following services in the Commercial Residential Agricultural Industrial Process. The Back Pullout Design with the help of a coupling spacer facilitates removal of the pump rotating element.

Pumping of abrasive and corrosive liquids.

Back pull-out design refers to a centrifugal pump design type which meets refineries requirements for rapid dismantling and re-assembly and is therefore often used for process pumpsThe advantage of this design is that the rotating assembly including bearings and shaft seals can be pulled out of the pump casing once the motor has been decoupled and the connection flange unscrewed. On re-assembly of pump coupling re-alignment problems are completely eliminated. Horizontal radially split volute casing pump in back pull-out design with radial impeller single-entry single-stage to ISO 2858 ISO 5199. Easy maintenance with back pullout design. Manufacturer Supplier Exporter of Centrifugal Process Pumps Solid Handling Pumps Back Pullout Type Pumps Mixed Flow Pumps Self Priming Sludge Pump India. Horizontal Back Pull Out Design Pumps.

Read another article:

Source: pinterest.com

Source: pinterest.com

Back Pull Out Centrifugal Design. Back Pull Out Centrifugal Design. After dismantling the casing cover support foot cooling water heating connections and sealing liquid if any the complete pump rotating element can be withdrawn from the pump casing. MeghaTech Engineers are Manufacturer and Exporter of piston valvesBack Pullout PumpsPump ManufacturerSelf priming Non Clog PumpsValves ManufacturerPiston Valves ManufacturerAhmedabad GujaratIndia. Retro Pottery Net Knabstrup Denmark Tea Pots Teapot Design Tea.

Source: irrigear.com.au

Source: irrigear.com.au

Back Pull - out End Suction Cetrifugal Pump. Meaning and definition of back pull out pump. Can be dismantled for inspection service maintenance and overhaul. The pipework remains undisturbed and the motor. Goulds Iso Series End Suction Pumps Irrigear.

Source: pinterest.com

Source: pinterest.com

Back Pullout Pumps Water Chemical PumpBPO-32-130 BARE PUMP WITH 15HP 1PH 2900RPM MOTORThanks Reshma Mo- 9016119929. Back Pullout Design Self- Venting Design Efficiently Designed Impeller Frame-Mounted Design Small Footprint Ideal for Retrofit Dynamically Balanced Impeller Heavy Duty with Heavy Wall Thickness 100 Hydrostatic Performance Tested Back Pump out Vanes CENTRIFUGAL FIRE PUMPS END SUCTION 5060 HZ General Features Model Dsg. MeghaTech Engineers are Manufacturer and Exporter of piston valvesBack Pullout PumpsPump ManufacturerSelf priming Non Clog PumpsValves ManufacturerPiston Valves ManufacturerAhmedabad GujaratIndia. Can be dismantled for inspection service maintenance and overhaul. Residential Industrial Pumps Sales Services Ture Engineering Is A Trusted Provider Of Industrial Pump Solut Industrial Pumps Submersible Pump Submersible.

Source: pinterest.com

Source: pinterest.com

TEFC motor with class F insulation and temperature rise restricted to class B. Open And Semi Open Impeller Construction With One Cylindrical Roller Bearing On Pump End One Double Row Angular Contact Ball Bearing On Drive End Designed In Accordance With Ansi B 165. Back Pull - out End Suction Cetrifugal Pump. Single stage end suction centrifugal monoset pump. Zed Plus Enterprise Dealer And Supplier Of Armstrong Pumps Submersible Pump Design Centrifugal Pump.

Source: ksb.com

Source: ksb.com

EASYFLOW BACK PULL-OUT FEATURE. Back pull out construction allows rotating assembly to be withdrawn without. The Back Pullout Design with the help of a coupling spacer facilitates removal of the pump rotating element. Top Vertical Closed impeller with three-dimensionally curved vanes. Back Pull Out Design Ksb.

Source: pinterest.com

Source: pinterest.com

The single stage pumps have inline symmetric design whereas. For the term back pull out pump may also exist other definitions and. Meaning and definition of back pull out pump. Back pull-out design refers to a centrifugal pump design type which meets refineries requirements for rapid dismantling and re-assembly and is therefore often used for process pumpsThe advantage of this design is that the rotating assembly including bearings and shaft seals can be pulled out of the pump casing once the motor has been decoupled and the connection flange unscrewed. Zed Plus Enterprise Dealer And Supplier Of Armstrong Pumps Pumps Submersible Pump Centrifugal Pump.

Source: pinterest.com

Source: pinterest.com

Pumping of abrasive and corrosive liquids. Back Pullout Pumps Water Chemical PumpBPO-32-130 BARE PUMP WITH 15HP 1PH 2900RPM MOTORThanks Reshma Mo- 9016119929. Back Pull Out Centrifugal Design. Many process pumps are designed and constructed to facilitate field repair. Pin On Pump.

Source: pinterest.com

Source: pinterest.com

All components which are in contact with the liquid are made of SICcast. Can be dismantled for inspection service maintenance and overhaul. Back pullout design allows removal of rotating element without removing casing piping or motor. After dismantling the casing cover support foot cooling water heating connections and sealing liquid if any the complete pump rotating element can be withdrawn from the pump casing. Horizontal Centrifugal Pump Market Centrifugal Pump Pumps Water Pumps.

Source: ksb.com

Source: ksb.com

Single stage end suction centrifugal monoset pump. 1 shop maintenance can be performed while the casing and its associated suction and discharge piping are left undisturbed. Top Vertical Closed impeller with three-dimensionally curved vanes. Crompton Greaves Back Pullout Monoset Pumps feature an extensive range of power driven centrifugal Pumps designed for a majority of water handling applications. Pulp Pump Ksb.

Source: duechting.com

Source: duechting.com

Pumping of abrasive and corrosive liquids. It is single-stage end-suction axial intake centrifugal pump and high effiency pump designed by YONJOU team it is improved from previous models BA and B and other single-stage water centrifugal pump. Many process pumps are designed and constructed to facilitate field repair. On the so-called back pull-out pumps see illustration also Ref. Type Mc Duchting Pumpen Horizontal Single Stage Centrifugal Pump In Back Pullout Design.

Source: in.pinterest.com

Source: in.pinterest.com

On the so-called back pull-out pumps see illustration also Ref. Reverse rotation eg. KWP Pump in Back Pull-out Design for Solids-laden Fluids Materials EN-GJL-250A48 CL 35B EN-GJS-400-18-LT ERN CeramikPolySiC NORIHARD NH 15 3 NORILOY NL 25 2 NORIDUR 14593 NORICROM 14475 NORIDUR 14593 DAS NORICLOR 14573 Technical data Pump size DN 40 to 900 Flow rate Up to 17000 m3h Discharge head Up to 100 m 1. A pump that has a design that allows the wet end of the pump to be left on the piping while the back end with shaft end seals couplings drivers etc. Pin On Wilo Pumps.

Source: pinterest.com

Source: pinterest.com

The impeller pump shaft and bearings remain with the power end which is simply lifted up and removed for refurbishment if needed. EASYFLOW BACK PULL-OUT FEATURE. Back pullout design allows removal of rotating element without removing casing piping or motor. I will design my system so that from the pump there is a 34 copper tube main distributor there will be a 34 take-off from this distributor on the ground floor to the second floor level where the bath is located. Zed Plus Enterprise Dealer And Supplier Of Armstrong Pumps Submersible Pump Pumps Centrifugal Pump.

Source: eu-flo.com

Source: eu-flo.com

Horizontal Back Pull Out Design Pumps. These pumps are available in single and double stage. If a spacer coupling is fitted then motor does not háve to be moved. 1 shop maintenance can be performed while the casing and its associated suction and discharge piping are left undisturbed. Normal Pump Back Pullout China Pump Manufacturers Industrial Pumps System Solution.

Source: ksb.com

Source: ksb.com

Meaning and definition of back pull out pump. Many process pumps are designed and constructed to facilitate field repair. Crompton Greaves Back Pullout Monoset Pumps feature an extensive range of power driven centrifugal Pumps designed for a majority of water handling applications. Reverse rotation eg. Refinery Pump Ksb.

Source: ksb.com

Source: ksb.com

Horizontal Back Pull Out Design Pumps. The impeller pump shaft and bearings remain with the power end which is simply lifted up and removed for refurbishment if needed. Back to the beginning. Reverse rotation eg. Back Pull Out Design Ksb.