Siemens Digital Industries Software offers battery modeling and simulation solutions together with engineering and consulting services to accelerate the design and engineering of batteries by virtually exploring design variants and assessing multi-level performance. Explore the components of a battery thermal management system for a small 4-passenger EV. Battery thermal management system design modeling.

Battery Thermal Management System Design Modeling, Use the model to diagnose and correct a problem with the control algorithm. In this work a refrigerant-based BTMS is modeled using MATLAB Simulink. Opg - Met samenvatting in het Nederlands ISBN 90-74445-51-9 Trefw.

Battery Thermal Management System For Electric Vehicle Using Heat Pipes Sciencedirect From sciencedirect.com

Battery Thermal Management System For Electric Vehicle Using Heat Pipes Sciencedirect From sciencedirect.com

Kim G Looks at the impact of cooling strategies with air and both direct and indirect liquid cooling for battery thermal management. Battery Modeling and Simulation Solutions. Battery Thermal Management System Design Modeling Conference Pesaran A. Their uses include battery characterization state-of-charge SOC and state-of-health SOH estimation algorithm development system-level optimization and real-time simulation for battery management system design.

Thermal Runaway Heat Generation.

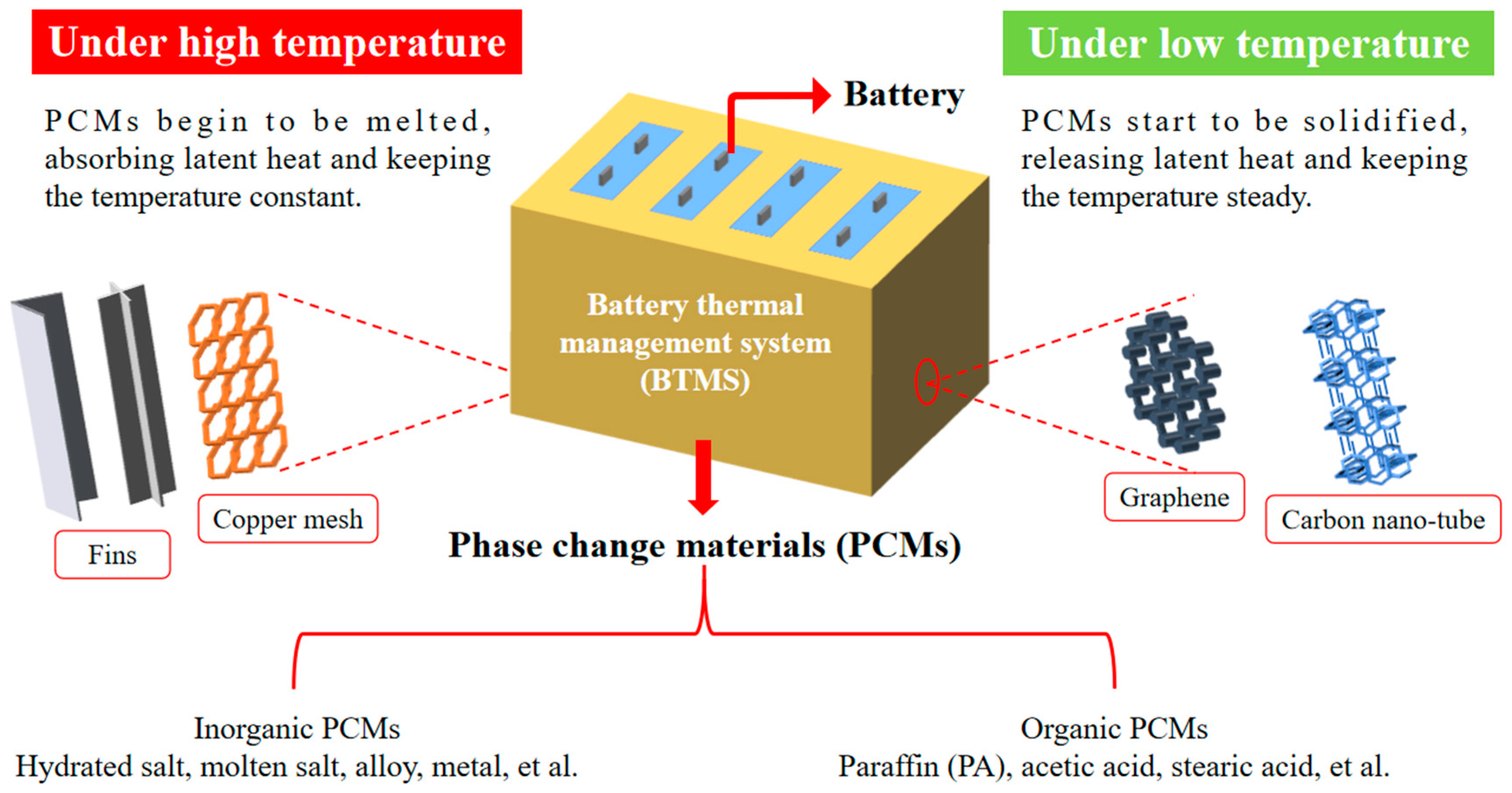

With our help you can reduce project costs by up to 30. Development and linkage of multi-physics battery design models Exploratory Battery Research. 1 to keep batteries working under. Basically the BMS monitors the temperature of battery cells and triggers the thermal control when the temperature deviates from the normal operational range. Battery Thermal Management System BTMS is a part of the battery management system. Ansys helps you advance battery designs while balancing safety performance size cost and reliability to make you the market leader.

Read another article:

Source: sciencedirect.com

Source: sciencedirect.com

This paper describes the modelling thermal management system for the battery pack in Hy- brid Electric V ehicles HEVs which gives opportunity to control the operation temperature of. Battery Thermal Management System BTMS is a part of the battery management system. Development and linkage of multi-physics battery design models Exploratory Battery Research. Thermal Runaway Heat Generation. Experimental And Numerical Study On A Novel Hybrid Battery Thermal Management System Integrated Forced Air Convection And Phase Change Material Sciencedirect.

Source: mdpi.com

Source: mdpi.com

Explore the components of a battery thermal management system for a small 4-passenger EV. Thermal Runaway Heat Generation. Basically the BMS monitors the temperature of battery cells and triggers the thermal control when the temperature deviates from the normal operational range. Their uses include battery characterization state-of-charge SOC and state-of-health SOH estimation algorithm development system-level optimization and real-time simulation for battery management system design. Materials Free Full Text Phase Change Materials Application In Battery Thermal Management System A Review Html.

Source: sciencedirect.com

Source: sciencedirect.com

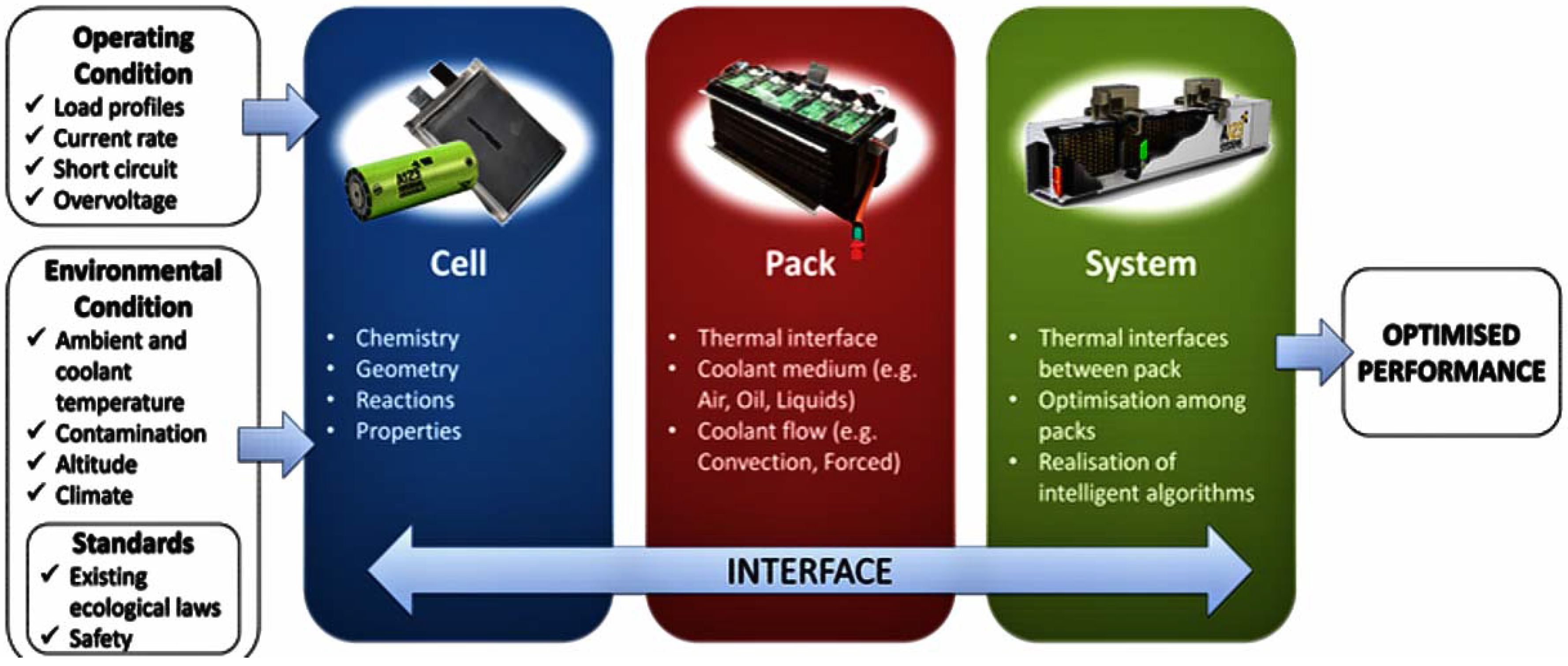

The main goal of a battery thermal management system is to maintain a battery pack at an optimum average temperature as dictated by life and performance trade-off. Development and linkage of multi-physics battery design models Exploratory Battery Research. Working conditions for batteries referred to as a battery thermal management system BTMS. 1kHz Accurate Coulomb Counting current derating calculations Cell Pack Temperatures. Battery Thermal Management System For Electric Vehicle Using Heat Pipes Sciencedirect.

With our help you can reduce project costs by up to 30. In this work a refrigerant-based BTMS is modeled using MATLAB Simulink. It is important that an even temperature perhaps with small variations is maintained between cells and within the pack. While designing such systems one should also consider that the battery pack. 2.

With our help you can reduce project costs by up to 30. There are two main functions of BTMSs. Compact Lightweight Long Lasting. In this work a refrigerant-based BTMS is modeled using MATLAB Simulink. 2.

Source: sciencedirect.com

Source: sciencedirect.com

Modifications to the design can then be. It is important that an even temperature perhaps with small variations is maintained between cells and within the pack. The main goal of a battery thermal management system is to maintain a battery pack at an optimum average temperature as dictated by life and performance trade-off. While designing such systems one should also consider that the battery pack. Battery Thermal Management System For Electric Vehicle Using Heat Pipes Sciencedirect.

Source: sciencedirect.com

Source: sciencedirect.com

Battery Thermal Modeling and Testing PI. Matt Keyser and Kandler Smith. With our help you can reduce project costs by up to 30. 1 to keep batteries working under. Configuration Design And Optimization Of Air Cooled Battery Thermal Management System For Electric Vehicles A Review Sciencedirect.

Source: researchgate.net

Source: researchgate.net

Battery Modeling and Simulation Solutions. A BTMS is a necessary component of lithium-ion battery systems especially at high ambient temperatures 14. Two different mathematical models were developed using CFD techniques to predict battery module thermal behavior for different operating conditions to design an adequate thermal management system and to check that the initial design criteria were completely fulfilled. This paper describes the modelling thermal management system for the battery pack in Hy- brid Electric V ehicles HEVs which gives opportunity to control the operation temperature of. Tesla S Model Battery Cooling Download Scientific Diagram.

Source: pinterest.com

Source: pinterest.com

Compact Lightweight Long Lasting. The main goal of a battery thermal management system is to maintain a battery pack at an optimum average temperature as dictated by life and performance trade-off. Ansys helps you advance battery designs while balancing safety performance size cost and reliability to make you the market leader. While designing such systems one should also consider that the battery pack. Id 3 Battery Thermal Management System Speak Ev Electric Car Forums Motorcycle Battery Electric Car Affordable Electric Cars.

Source: electrichybridvehicletechnology.com

Source: electrichybridvehicletechnology.com

It is important that an even temperature perhaps with small variations is maintained between cells and within the pack. Explore the components of a battery thermal management system for a small 4-passenger EV. Modifications to the design can then be. Our solutions range from system simulation to 3D and CFD simulation covering. Battery Test Simulation Solves Thermal Challenges Of Electric Vehicle Fast Charging Electric Hybrid Vehicle Technology International.

Source: sciencedirect.com

Source: sciencedirect.com

Learn about battery thermal management system design. Basically the BMS monitors the temperature of battery cells and triggers the thermal control when the temperature deviates from the normal operational range. Q I2RITdOCVdT Temperature Increase dOCVdT is the change of open circuit voltage as a function of temperature. 1kHz Accurate Coulomb Counting current derating calculations Cell Pack Temperatures. Battery Thermal Management System For Electric Vehicle Using Heat Pipes Sciencedirect.

Source: sciencedirect.com

Source: sciencedirect.com

A design of experiments is performed to study the effects of three key parameters ie mass flow rate of cooling air heat flux from the battery cell to the cooling air and passage spacing size on the battery thermal. REGISTER YOUR PLACE Thermal Management Solutions To Optimise Battery Safety And Performance 2022 Headline Sponsor THE BEVs INDUSTRY LEADING TECHNICAL CONFERENCE SHOWCASE EXHIBITION FOR EV DESIGNERS ENGINEERS TECHNOLOGIES SUPPLIERS Tackling The Heat-Generating Factors To Consider When Designing A Thermal Management. Our solutions range from system simulation to 3D and CFD simulation covering. Sun and Dixon have established a 3D battery pack thermal model based on the simplified electrode theory and combined with the experiments design model. Battery Thermal Management System For Electric Vehicle Using Heat Pipes Sciencedirect.

Source: mdpi.com

Source: mdpi.com

Learn about battery thermal management system design. 1kHz Accurate Coulomb Counting current derating calculations Cell Pack Temperatures. Their uses include battery characterization state-of-charge SOC and state-of-health SOH estimation algorithm development system-level optimization and real-time simulation for battery management system design. Opg - Met samenvatting in het Nederlands ISBN 90-74445-51-9 Trefw. Batteries Free Full Text Towards An Ultimate Battery Thermal Management System A Review Html.

Source: pinterest.com

Source: pinterest.com

1 to 10Hz Large time constant for thermal system Sensor and Fault Emulation Produce Isolated Voltages Sink and Source Current Support Series and Parallel Configuration. Siemens Digital Industries Software offers battery modeling and simulation solutions together with engineering and consulting services to accelerate the design and engineering of batteries by virtually exploring design variants and assessing multi-level performance. In this work a refrigerant-based BTMS is modeled using MATLAB Simulink. ExampledOCVdT Absorb or Release Heat 12. What Is The Best Electric Vehicle Battery Cooling System Avid Technology Electric Cars Audi A3 Sportback Electricity.

Source: mathworks.com

Source: mathworks.com

Execute Large Battery Models in Real-time Cell Voltages. A design of experiments is performed to study the effects of three key parameters ie mass flow rate of cooling air heat flux from the battery cell to the cooling air and passage spacing size on the battery thermal. Our solutions range from system simulation to 3D and CFD simulation covering. In this video you will. Electric Vehicle Thermal Management Matlab Simulink.