If not given assume q 11. Calculation of diameter factor and lead angle. Axle design procedure.

Axle Design Procedure, Tra c distribution along the lanes are taken into account. From 1 to 10 with the higher number indicating a. A turn needing to trace out circles of different radius.

Car Suspension Basics How To Design Tips Free From buildyourownracecar.com

Car Suspension Basics How To Design Tips Free From buildyourownracecar.com

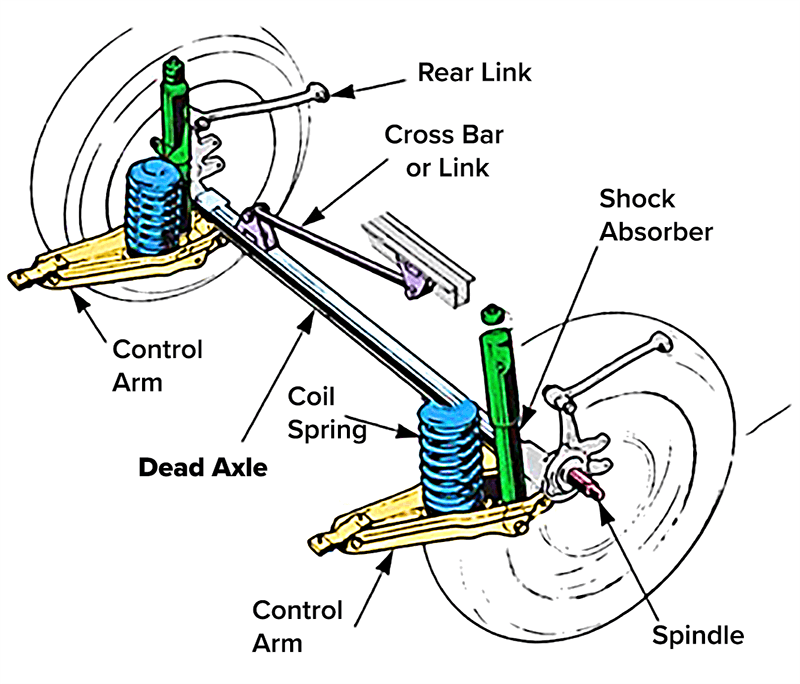

From 1 to 10 with the higher number indicating a. SUSPENSION SYSTEM The suspension of vehicles needs to satisfy a number of requirements which depend on different operating conditions of the vehicle. The Axle-X Interspinous Fusion System is an alternative construct with angled spikes that allows for adequate L5-S1 engagement and other variations in patient anatomy. Design of Track Sections The design of axle counter sections should be based on the operational needs for train movements and not on requirements for sweep trains during reset.

The main purpose of the axle loads for trucks survey is to collect preliminary information regarding the range of heavy axle loads traversing the nations main highways.

Next have students disconnect the wheel axle from the structure. D Divide n i by N i to determine erosion damage factor d i. SUSPENSION SYSTEM The suspension of vehicles needs to satisfy a number of requirements which depend on different operating conditions of the vehicle. Tra c distribution along the lanes are taken into account. Which expresses varying axle loads and traffic. ɤ tan-1 z1q 4.

Read another article:

Source: sciencedirect.com

Source: sciencedirect.com

Drive Axles An Overview Sciencedirect Topics A Determine N i for fatigue failure. P j i N Annual Average Daily Traffic Traffic Growth Rate Design Life Period 20 yrs. 2-axle car design principles are used mainly for European freight cars shunting locomotives and for sections of articulated cars such as low-floor light rail vehicles or tramways. DESIGN PROCEDURE FOR WORM GEAR.

Source: sciencedirect.com

Source: sciencedirect.com

Axles An Overview Sciencedirect Topics The axle pivot should also be wear resistant and have low friction. If not given assume q 11. Determination of design parameters for suspension system. ü Assume Z 1 depending upon the number of stat.

Source: thecartech.com

Source: thecartech.com

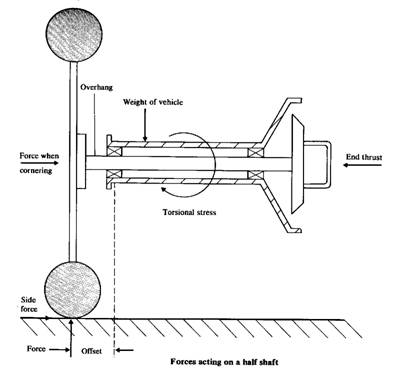

Axle Shafts ADT average percent trucks average number of axles per truck and average load distribution of truck axles composite axle-load distribution 2. A calculation of the components of moments is done along each one of the three principal directions in order to obtain the resultant moment. Engineering Road Note 9 outlines the procedure to be used for the design of road pavements that have a bituminous or concrete wearing course and are under the control of the Commissioner of Main Roads Western Australia. PROCEDURE IN COMPUTING THE CUMULATIVE EQUIVALENT SINGLE AXLE LOAD CESAL 1.

Source: buildyourownracecar.com

Source: buildyourownracecar.com

Car Suspension Basics How To Design Tips Free ü Z 2 i X Z 1. Calculation of Tangential load. Which expresses varying axle loads and traffic. A simple approximation to perfect Ackermann steering geometry may be generated by moving the steering pivot points inward so as to lie on a line drawn between the steering kingpins and the center of the rear axle.

Source: buildyourownracecar.com

Source: buildyourownracecar.com

Car Suspension Basics How To Design Tips Free ü Assume Z 1 depending upon the number of stat. C Determine N i for erosion failure. Design of Track Sections The design of axle counter sections should be based on the operational needs for train movements and not on requirements for sweep trains during reset. DESIGN PROCEDURE FOR WORM GEAR.

Source: drivesmartwarranty.com

Source: drivesmartwarranty.com

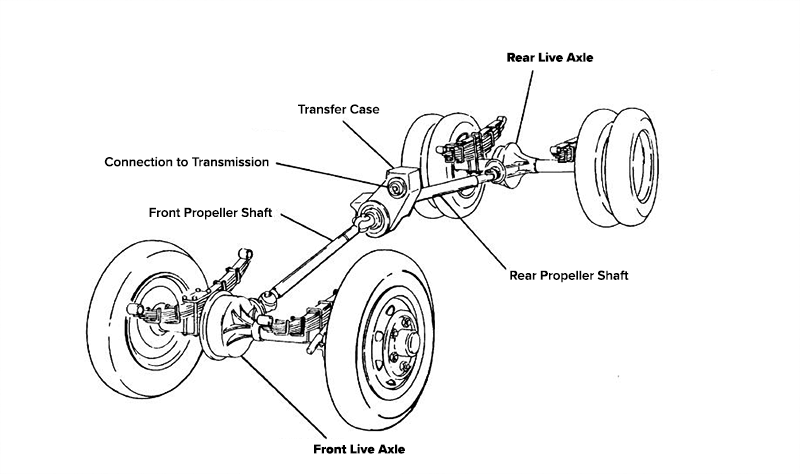

What Is A Drive Axle How Drive Axles Work Axle has sufficiently rigidly and strength to transmit the weight of the vehicle from springs to the front wheels. For each axle load class. ADT average percent trucks average number of axles per truck and average load distribution of truck axles composite axle-load distribution 2. Next have students disconnect the wheel axle from the structure.

Source: pinterest.com

Source: pinterest.com

Komatsu Wa900 3 Wheel Loader Field Assembly Manual 50001 And Up Gen00019 00 Washer Fluid Komatsu Manual The ends of the axle beam are usually shaped either as yoke or plain surface with drilled hole for connecting the stub axle assembly. Specific applications like front bucket bund preparation and paddy field demand very rigid axle design. DESIGN PROCEDURE FOR WORM GEAR. P j i N Annual Average Daily Traffic Traffic Growth Rate Design Life Period 20 yrs.

Source: sciencedirect.com

Source: sciencedirect.com

Axles An Overview Sciencedirect Topics The axle loads are multiplied by the load safety factor for Column 2. ADT average percent trucks average number of axles per truck and average load distribution of truck axles composite axle-load distribution 2. If using cambered axle locate and mark the upper camber line top dead centre of the axles. Calculation of diameter factor and lead angle.

Source: pinterest.com

Source: pinterest.com

Science Fair Projects Wheel And Axle Model Youtube Science Fair Projects Fair Projects Science Fair The design construction and maintenance of road pavements involve the management of risks. P j i N Annual Average Daily Traffic Traffic Growth Rate Design Life Period 20 yrs. A calculation of the components of moments is done along each one of the three principal directions in order to obtain the resultant moment. Ensure that the axle makes contact with the bottom of the axle seat as shown.

Source: drivesmartwarranty.com

Source: drivesmartwarranty.com

What Is A Drive Axle How Drive Axles Work A Determine N i for fatigue failure. 2-axle car design principles are used mainly for European freight cars shunting locomotives and for sections of articulated cars such as low-floor light rail vehicles or tramways. The step-by-step design procedure is as follows. The ends of the axle beam are usually shaped either as yoke or plain surface with drilled hole for connecting the stub axle assembly.

Source: pinterest.com

Source: pinterest.com

Our Open Minded Technical Team Has Made A Great Contribution To The Company Operation And Development We Strictl Trailer Axles Landing Gear Trailer Suspension A turn needing to trace out circles of different radius. Determine the Traffic Equivalence Factor EF for each vehicle type. Outside of these particular areas the Bison Pullers allowed our team free reigns to the overall design of the front axle. Selection of the material.

Source: sciencedirect.com

Source: sciencedirect.com

Axles An Overview Sciencedirect Topics ADT average percent trucks average number of axles per truck and average load distribution of truck axles composite axle-load distribution 2. ɤ tan-1 z1q 4. Designand optimization of suspension system. Calculation of diameter factor and lead angle.

Source: what-when-how.com

Source: what-when-how.com

Front Axle Automobile C Determine N i for erosion failure. Tra c distribution along the lanes are taken into account. The first design goal and likely most important goal set by the Bison Pullers was the weight. Calculation of diameter factor and lead angle.

Source: in.pinterest.com

Source: in.pinterest.com

Best Car Cover Car Axle Thru Axle Rear Axle Front Axle Stub Axle C V Axle Car Axle Car Covers Automobile Technology Engineering Road Note 9 outlines the procedure to be used for the design of road pavements that have a bituminous or concrete wearing course and are under the control of the Commissioner of Main Roads Western Australia. The design procedure given by IRC makes use of the CBR value million standard axle concept and vehicle damage factor. This is essential so that for Road Engineers can design a more robust road network without going into frequent maintenance due to poorly designed roads and pavements. These design data are then compared.

Source: pinterest.com

Source: pinterest.com

Custom Procedures Lockout Tagout Custom Computer Aided Drafting However the position of axle counter heads for point sections should be close to the clearance point of the diverging paths of the point where possible. A calculation of the components of moments is done along each one of the three principal directions in order to obtain the resultant moment. The main purpose of the axle loads for trucks survey is to collect preliminary information regarding the range of heavy axle loads traversing the nations main highways. Ensure that the axle makes contact with the bottom of the axle seat as shown.