Design Condenser TD Condensing Temp Ambient Temp 110 95 20 TD. An air cooled condenser ACC is a direct dry cooling system where steam is condensed inside air-cooled finned tubes. Air cooled condenser design calculation excel.

Air Cooled Condenser Design Calculation Excel, Condenser design software for shell and tube heat exchangers. 1 Evaporation cooling Thermocompressor design. Step of the analysis has been the design calculation of the condenser main operating parameters.

Room Air Conditioning Size Calculator Excel Sheet Room Air Conditioning Refrigeration And Air Conditioning Room Air Conditioner From pinterest.com

Room Air Conditioning Size Calculator Excel Sheet Room Air Conditioning Refrigeration And Air Conditioning Room Air Conditioner From pinterest.com

An air cooled condenser ACC is a direct dry cooling system where steam is condensed inside air-cooled finned tubes. Condenser design software for shell and tube heat exchangers. As condensers and reboilers. In environments where lower noise levels are desired the air velocity will also be reduced.

Innospin has realized more than 60 air-cooled condenser projects.

Of Rows 2 No. These capacities are given in MBHTD. Then divide the THR by the design TD to get. The air velocity recommended for air cooled condenser design at standard noise levels is around 30-40 ms. Air Cooled Condenser Design Spreadsheet - Download as Excel Spreadsheet xls PDF File pdf. 01 April 2011 At least two fans shall be provided for each bay.

Read another article:

Source: engproguides.com

Source: engproguides.com

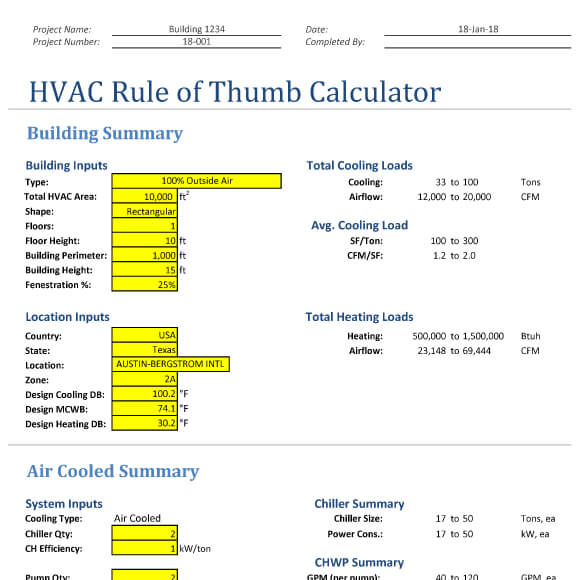

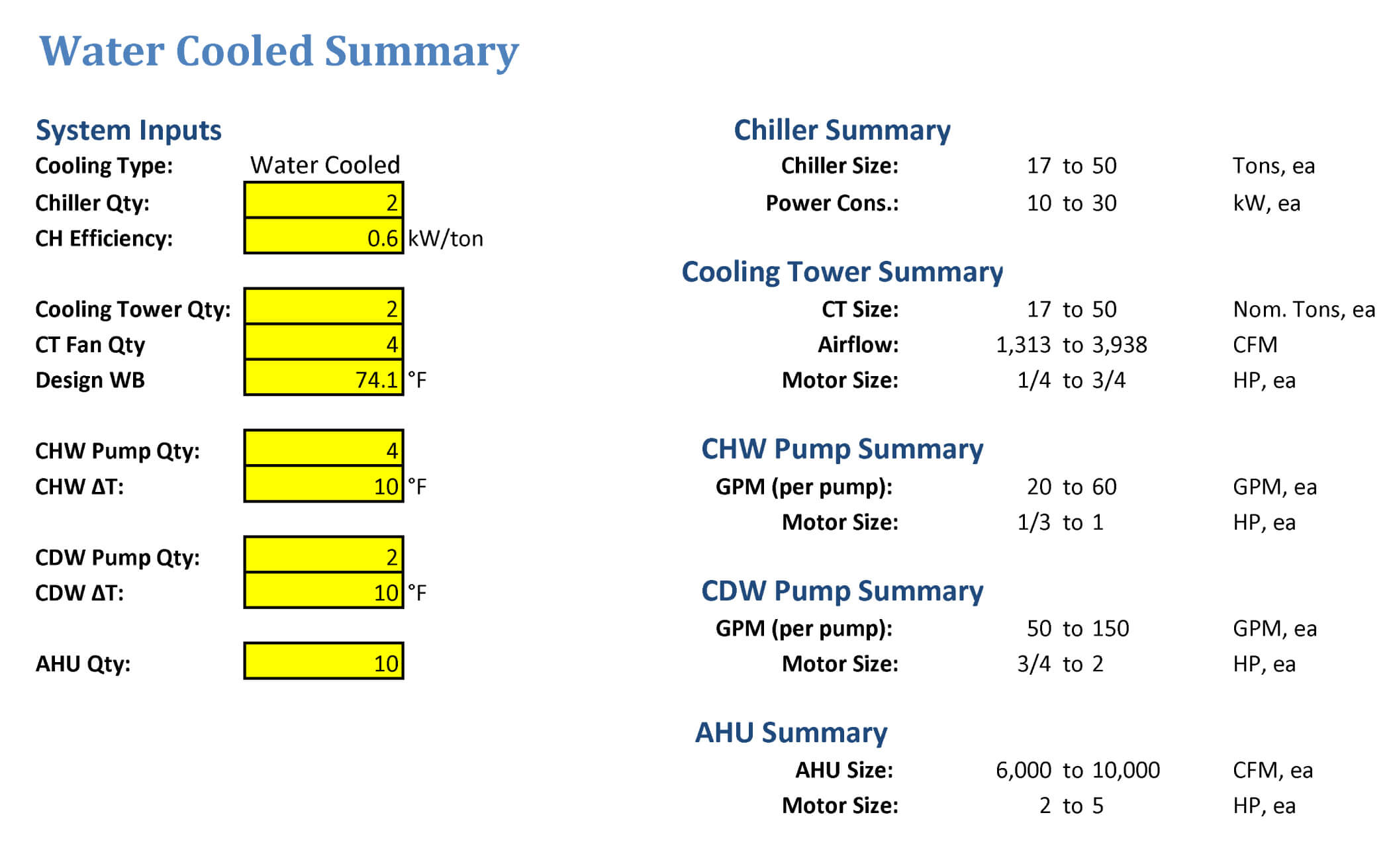

Hvac Rule Of Thumb Excel Calculator Design Tools Condenser capacities for 60 Hz are located in Table 4. The air velocity recommended for air cooled condenser design at standard noise levels is around 30-40 ms. Perform condenser design calculations using various correlations presented for estimating heat transfer coefficients on external fluid and refrigerant side and estimate the required condenser area for a given refrigeration system 4. Free Excel condenser calculation tool.

Source: brighthubengineering.com

Source: brighthubengineering.com

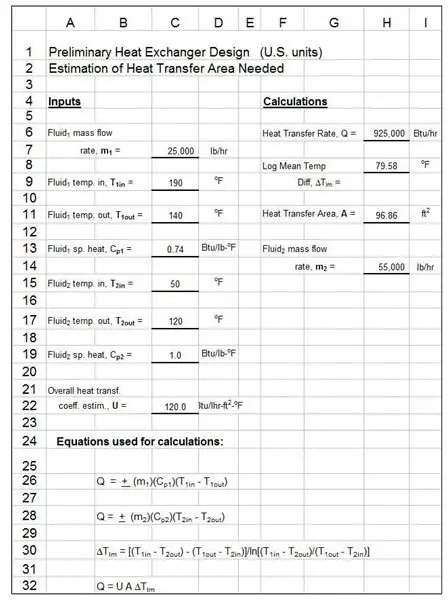

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering PROCESS DESIGN OF AIR COOLED HEAT EXCHANGERS AIR COOLERS PROJECT STANDARDS AND SPECIFICATIONS Page 5 of 19 Rev. Detailed calculation than displays many calculated variables such as. Step of the analysis has been the design calculation of the condenser main operating parameters. Condenser design software for shell and tube heat.

Air Cooled Condenser Design Spreadsheet Pdf Heat Exchanger Energy Technology Normally around 750 to 1000 cfm per TR is required and again depends on the suction and discharge. Perform condenser design calculations using various correlations presented for estimating heat transfer coefficients on external fluid and refrigerant side and estimate the required condenser area for a given refrigeration system 4. A small air-cooled condenser was run under the ambient air temperature extremes of Las Vegas in order to examine the system performance and air-side heat transfer parameters. Condenser capacities for 60 Hz are located in Table 4.

Source: pinterest.com

Source: pinterest.com

Download A Free Calculation Excel Sheet For Pump Head Calculations For Chilled Wa Refrigeration And Air Conditioning Water Pump System Central Air Conditioning Compare air-cooled condensers with water-cooled condensers 3. Calculate Design Condenser TD. If the ratio is more Heat rejection factor will be more. Calculate temperature at the cooling box for given mass flowrate of motion steam.

Source: brighthubengineering.com

Source: brighthubengineering.com

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering Of Tubes 110 No. Equations and Parameters The heat exchanger design equation Q U A ΔT lm can be used to determine the required heat transfer area A for a heat exchanger. Calculate the capacity rate ratio. For this purpose the two-phase fluid normally flows axially in a single pass rather than spirally.

Source: engproguides.com

Source: engproguides.com

Hvac Rule Of Thumb Excel Calculator Design Tools Detail design and construction drawing must always be done with the support of such a company. Air Cooled Condenser Design Spreadsheet - Free download as Excel Spreadsheet xls PDF File pdf Text File txt or read online for free. You can access a free Excel calculation tool to size a shell-tube condenser or control the size of an existing condenser as explained above. Calculate the overall heat transfer coefficient.

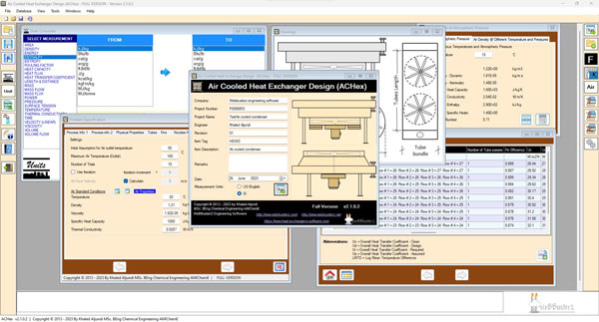

Air Cooled Condenser Design Spreadsheet Pdf Transport Phenomena Thermodynamics Import physical properties data to hot side and cold side from Microsoft Excel from WeBBusterZ Physical properties database. Condenser Design Calculation Excel. Of Rows 2 No. Air Cooled Condenser Design Spreadsheet - Download as Excel Spreadsheet xls PDF File pdf.

Source: air-cooled-heat-exchanger-design.soft112.com

Source: air-cooled-heat-exchanger-design.soft112.com

Air Cooled Heat Exchanger Design 2 0 0 1 Free Download Fans in Various Duties Where for reasons of control an air-cooled heat exchanger has to be provided. Import physical properties data to hot side and cold side from Microsoft Excel from WeBBusterZ Physical properties database. Calculate the length of the tube or heat exchanger. Acc fan in power plant air cooled condenser capacity air cooled condenser design air cooled condenser design calculation excel air cooled condenser diagram air cooled condenser effeciency air cooled condenser manufacturers air cooled condenser ppt air cooled condensers for power plants air cooled condenser SlideShare air cooled condenser types air cooled condenser.

Source: pinterest.com

Source: pinterest.com

Pin On A New Matlab Simulink Model Has Arrived Check It Now Then divide the THR by the design TD to get. Then divide the THR by the design TD to get. The cool ambient air flow outside the finned tubes is what removes heat and defines the functionality of an ACC. Detailed calculation than displays many calculated variables such as.

Source: icemeister.net

Source: icemeister.net

Air Cooled Condenser Sizing Selection Any deviation from this requirement will need the prior approval of the Company. After all the test it is found that evaporatively cooled condenser has higher capacity by 18 to 81 higher COP by 111 to 216 and higher SEER by 145. Air cooled condenser surface area as well as air quantity is important. Condenser design software for shell and tube heat.

2 After all the test it is found that evaporatively cooled condenser has higher capacity by 18 to 81 higher COP by 111 to 216 and higher SEER by 145. Air cooled condenser surface area as well as air quantity is important. Condenser Design Calculation Excel. Flow a presentation for beginners.

Source: fasranalysis989.weebly.com

Source: fasranalysis989.weebly.com

Condenser Design Calculation Excel Fasranalysis Calculate Design Condenser TD. Condenser design software for shell and tube heat. Calculate the heat transfer surface area. Cross Flow Cooling Towers.

Source: pinterest.com

Source: pinterest.com

Carosella Design Build Explains What Is Going On With Your Home And Why You May Be Experiencing Coldness In Some Room Hvac System Cost Hvac Design Hvac System Condenser Design Calculation Excel. You can access a free Excel calculation tool to size a shell-tube condenser or control the size of an existing condenser as explained above. The air velocity recommended for air cooled condenser design at standard noise levels is around 30-40 ms. Thermal design calculations of Shell.

Source: buildinggreen.com

Source: buildinggreen.com

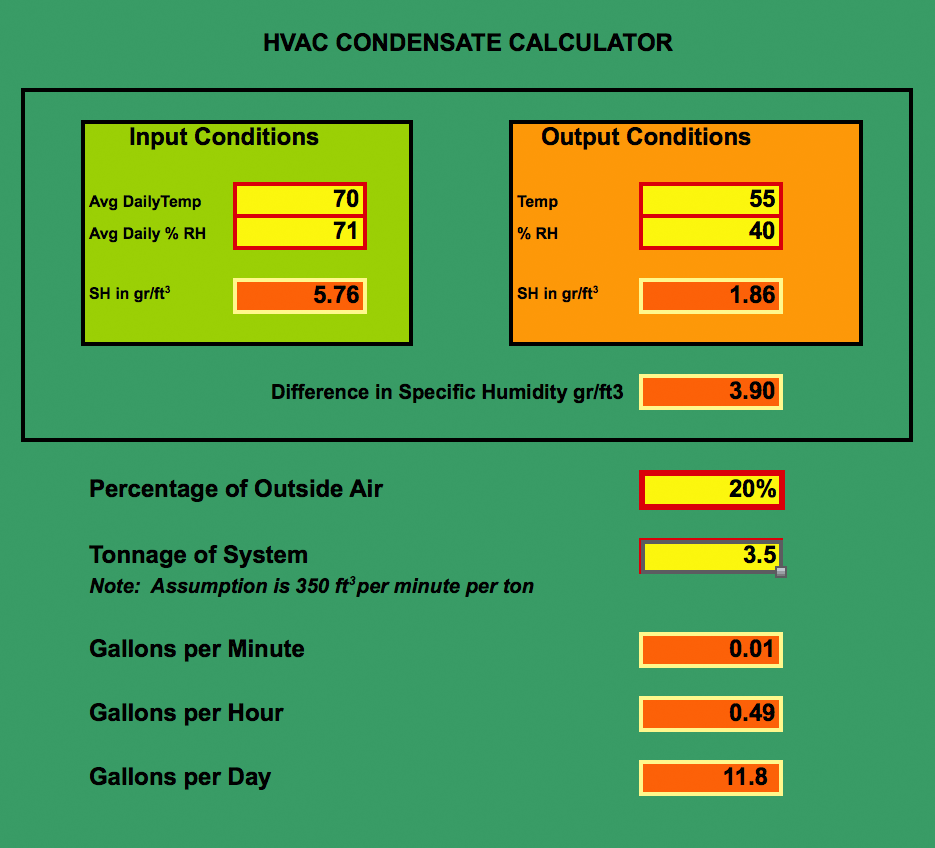

Revised Air Conditioner Condensate Calculator Available On Buildinggreen Com Buildinggreen Our range as general service contractor covers all activities from the feasibility study to the detail design and project realization. 5214 Air-Cooled Heat Exchangers It is sometimes economical to condense or cool hot streams inside tubes by blowing air across the tubes rather than using water or other cooling liquid. Compare air-cooled condensers with water-cooled condensers 3. PROCESS DESIGN OF AIR COOLED HEAT EXCHANGERS AIR COOLERS PROJECT STANDARDS AND SPECIFICATIONS Page 5 of 19 Rev.

Air Cooled Condenser Design Spreadsheet Pdf Heat Exchanger Energy Technology Modeling the performance characteristics of water-cooled Air-conditioners 9. Design Condenser TD Condensing Temp Ambient Temp 110 95 20 TD. Air Cooled Condenser Design Spreadsheet - Download as Excel Spreadsheet xls PDF File pdf. As condensers and reboilers.